SUBS

Command Tubular manufactures drill stem substitutes to API Spec 7-1 subs in the size range 2 7/8” large OD thru 14” large OD, 110,000 KSI – 130,000 KSI

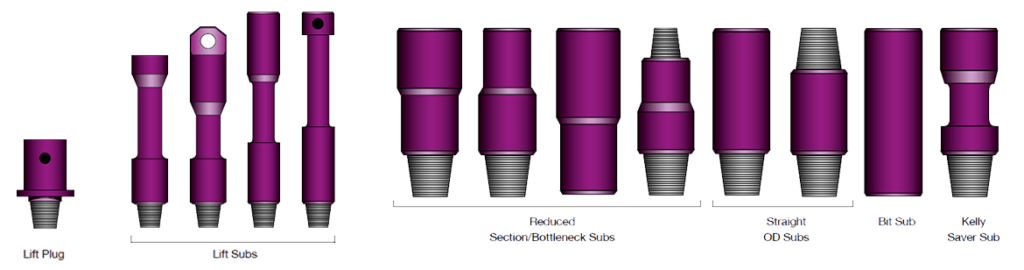

Standard Configurations:

- Straight OD

- Reduced section, bottleneck

- Swivel sub

- Lift sub

Non-Standard Configurations:

- Crossover sub

- Bit sub c/w float recess

- Saver sub

- Top drive sub

- Circulating sub

- Casing Running Subs

- Special application subs

The Highest Quality

- The highest quality and traceable 4145-H heat treated alloy steel bars are used to ensure optimum mechanical properties per API or NS-1. Upon request, as necessary, higher alloy steel with higher mechanical properties is available for increased wear resistance / torsional strength.

- All subs have unique serialization permanently marked with traceability to all manufacturers’ certified data meeting the specification requested.

- All API numbered, other common standard connections and Command Tubular proprietary CET™ and CDS™ double shouldered are machined on the latest CNC lathes. The threads of rotary shouldered, casing, tubing, line pipe and ACME connections are verified using all required precision gauges including working rings and plugs certified to API or proprietary master gauges.

- Threads can be cold rolled per NS-1 requirements. Phosphating of threads and seals is the standard anti-corrosion / anti-galling method used that minimizes galling on initial makeup.

- When requested, threads of rotary shouldered connections can be made up and broken to a specified percent of the maximum make up torque for a specified number of cycles (typically 3). This ensures optimum running performance without galling, particularly at the critical initial trip.

- Drawings and product data tables are available on request.

Our Subs

A crossover sub is used to crossover from one connection size to another or as the disposable component used to extend the connection life of a more expensive drill stem member.

Crossover subs are available with:

Crossover subs are available with:

- Box x Pin connections

- Box x Box connections

- Pin x Pin connections

Command Tubular’s top drive subs are manufactured to match the desired specifications for the top drive drill pipe required.

Drillable Pickup Subs are used to lift BHA components i.e. drilling motors, jars, shock tools, drill collars from the catwalk to the rig floor (similar to standard Lift Subs). The difference between the standard lift sub and “Drillable” lift subs is that the Drillable lift sub has a top box connection in place of the top cap, and can be left in the BHA component while drilling.

Pickup subs or lift subs are used to lift BHA components such as drilling motors, jars, shock tools, drill collars, etc. from the catwalk to the rig floor. Lift subs are screwed to the top of the tool and feature an elevator groove, engineered to API specifications that the rig uses to pick up the tool. They are also are available with any connection necessary.

Bit Subs are used to connect the drill bit to the first piece of BHA. Bit Subs can be ordered in sizes ranging from 3 1/8” to 11” OD, and various lengths made from 4145 Material. A Bottle Neck Bit Sub consists of two OD’s.

Bit Subs are used to connect the drill bit to the first piece of BHA. Bit Subs can be ordered in sizes ranging from 3 1/8” to 11” O.D., and various lengths made from 4145 Material. A Straight OD Bit Sub consists of one OD.

The Saver Sub is used to extend the life of the kelly by taking the connection wear each time it is made up to a drill stem component. The saver sub connection is sacrificed because it can be easily repaired or inexpensively replaced. The Saver Sub can be equipped with a rubber or brass protector to reduce BOP equipment and casing wear resulting from contact damage with the lower kelly connection.

Other Subs

Cementing Sub (side-entry)

Command Tubular’s cementing subs are made to order to meet customer specific requirements. The side-entry union is welded and MPI Inspected and can be pressure tested if required.

Circulating Sub

Command Tubular circulating subs are made to order to meet customer-specific requirements. Circulating subs are made of integral (one-piece) and can be pressure tested if required.

Command Tubular’s cementing subs are made to order to meet customer specific requirements. The side-entry union is welded and MPI Inspected and can be pressure tested if required.

Circulating Sub

Command Tubular circulating subs are made to order to meet customer-specific requirements. Circulating subs are made of integral (one-piece) and can be pressure tested if required.

Operational Benefits

Command Tubular Products offers a wide range drill string products and accessories with standard API or proprietary high-performance connections to meet the most demanding drilling requirements.

Drill stem subs are available in any size or configuration required.

Drill stem subs are available in any size or configuration required.